No products in the cart.

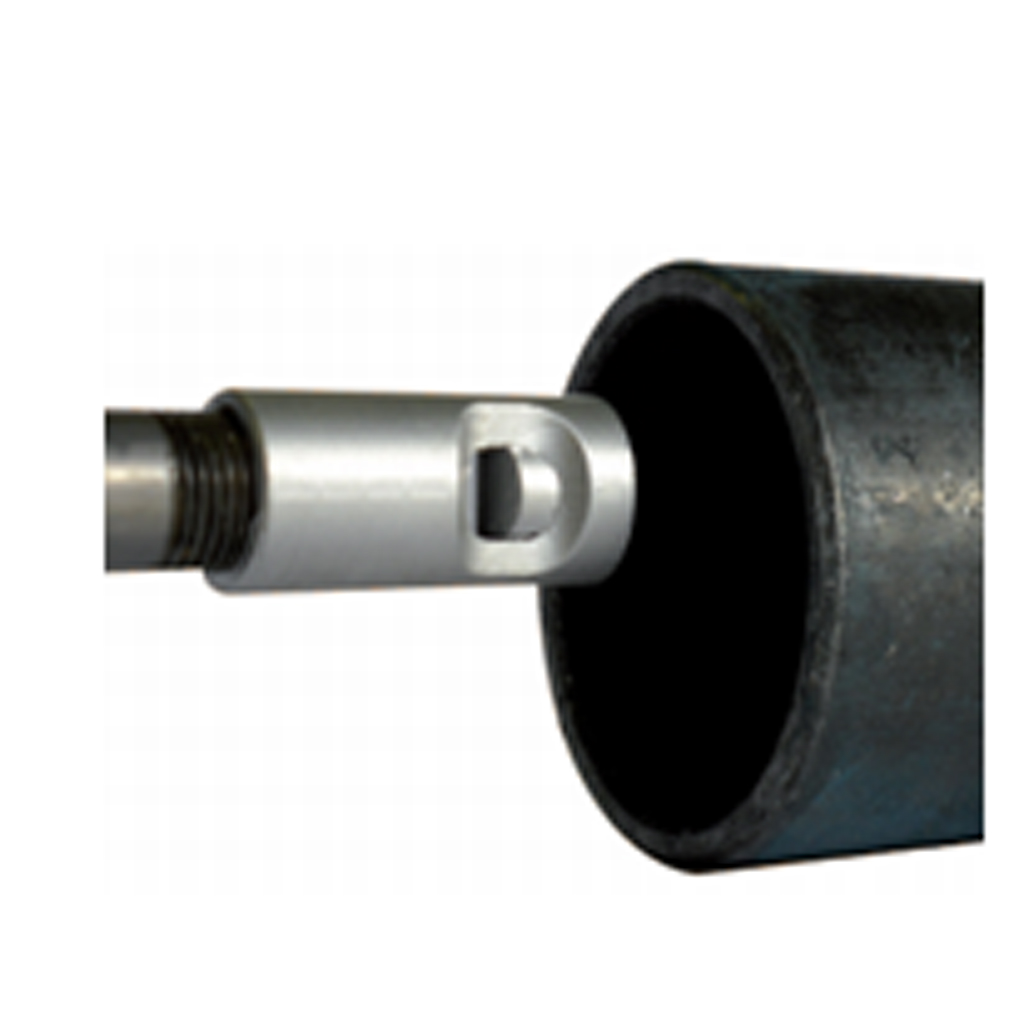

ASB-16 TC Spinnerblast Nozzle 9.5mm x 65mm

ASB-16 TC Spinnerblast Nozzle can be used for Spinnerblast Pipe cleaning machines.

Description

ASB-16 TC Spinnerblast Nozzle 8mm x 85mm

Can be used for Spinnerblast Pipe cleaning machines.

Airblast high velocity venturi style nozzles have been designed specifically to give maximum blast cleaning rates, uniform abrasive distribution and efficiency over an extensive operating life. Through the venturi principle the air and abrasive mixture is accelerated as it exits the nozzle. Venturi nozzles increase productivity and reduce abrasive consumption with approximately 40% as compared to straight bore nozzles. Airblast offers a full selection of nozzles with different orifice diameters, sizes, and insert / jacket materials.

Size

The orifice size of the blasting nozzle determines the cleaning rate, abrasive consumption and air consumption. When choosing a nozzle you should consider the cleaning rate required, available compressed air, size of the blast pot and the internal diameter of the piping, the blast hose and the air hose. In most blasting operations a number 5 (with 8 mm orifice) or number 6 (with 9,5 mm orifice) nozzle is used. Have a look at the consumption chart on the back of this datasheet for the compatible combinations.

Material

Material Tungsten carbide is the market standard and is a cost effective yet durable option. Silicon Carbide and Silicon Nitride nozzles are more wear resistant and reduce operator fatigue due to their light weight. Boron carbide nozzles offer the best resistance against wear.

As blast nozzles wear the orifice enlarges increasing air consumption and decreasing the venture effect resulting in slower abrasive speeds – nozzle wear should be monitored on a daily basis and worn nozzles replaced to maintain effective and efficient production

Downloads

Related products

ASB Tungsten Carbide Spinnerblast Nozzles

ASB Tungsten Carbide Spinnerblast Nozzles

ASB Tungsten Carbide Spinnerblast Nozzles

ASB Tungsten Carbide Spinnerblast Nozzles

CB-0 Circleblast – direct mounting on blast hose (1-1/4″ – 3″)